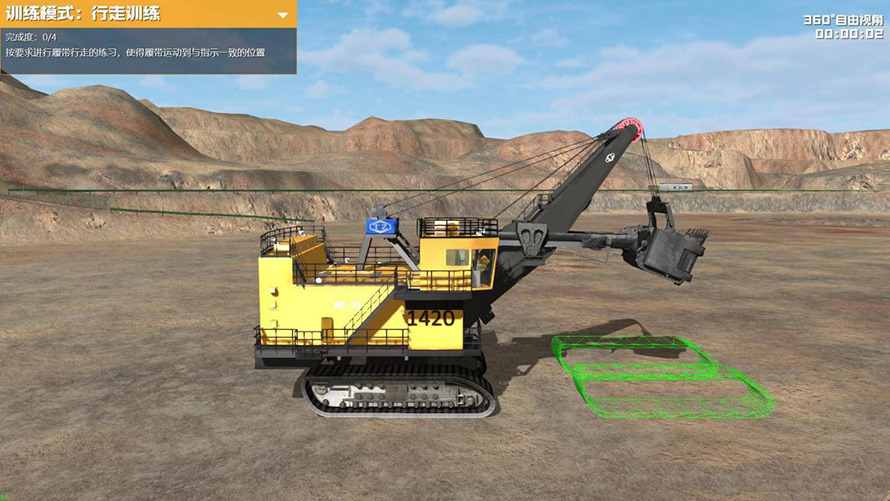

The simulator software adopts a multi-degree-of-freedom digital model to realize the realistic simulation of various turning, walking, and loosening shovel and dozer movements of the machine, and cooperate with loaders, excavators and other equipment to truly reproduce construction on the site. The software training topics are operated in accordance with four modes: basic training, assessment operation, collaborative work and theoretical study.

Construction machinery, mining machinery, fire-fighting production

1) Basic training topics include: 1. Walking practice 2. Pushing bricks 3. Dozing work 4. Backfilling ditches 5. Turning work 6. Leveling the ground 7. Removal of obstacles 8. Slope repairing 9. Empty movements 10. Freedom Functional modules such as job operations.

2) Cooperative operation mode: 1. Landslide (road clearing) 2. Earthquake repair 3. Barrier lake dredging 4. Mud-rock flow dredging 5. Snow disaster relief

3) Theoretical study includes:

a). Theoretical documents: including theoretical documents on bulldozer safety, operation, maintenance, etc., rich and detailed pictures and text descriptions solve the shortcomings of the lack of theoretical knowledge in training schools in teaching!

b) Teaching video: With this function, you can play various safety, maintenance, operation knowledge and other teaching videos of construction machinery operation, and provide students with practical and standardized actual real machine operation drills!

c) Theoretical assessment: Standardized test questions have been compiled based on the safety education and training syllabus and textbooks, and test questions can be added independently.

2. The simulation software provides two 3D models of different types (track type and tire type) for students to choose and practice.

The realization of a simulator allows students to practice different types of machine operation methods, provides training content, and lays a solid operating foundation for future graduation internships.

3. Realize true 3D visual effects through VR glasses.

The software cooperates with the VR glasses to realize the 3D effect function, which improves the students' interest in learning and operation effect.

4. Real-time evaluation system

After the students have operated each topic in the software, the system will judge whether the students are qualified according to their completion time and remaining scores, so that the students and teachers can understand the learning effect and adjust the teaching in time, and transmit them to the teacher through the LAN for storage or Print.

5. Personalized design for schools

After the teaching instrument is started, it will display the school name such as "Welcome to XXX Vocational and Technical College"!

6. Other functions of the software

The software also has related functions that other similar software does not have, such as: panoramic map is used to show the position of all equipment in the scene, various indicator lights alarm display, equipment operator name, operation time reminder, error operation reminder, etc. , Through the powerful software function combined with the hardware control system, so as to realize the indispensable role of the simulator in the whole training process of the school.

2.2 Hardware part

The equipment hardware consists of equipment base, cockpit, equipment seat, PC system, visual display, steering control rod, IC card reader, 360-degree view joystick, brake pedal, deceleration pedal, ripper control rod, data Collection system and various function buttons, etc. The equipment adopts the same operating parts as the real machine, and the realistic operating feel makes its operating function and operating feeling completely consistent with the real machine. Several important operating components are introduced as follows:

Left and right brake/deceleration pedals: The original brake pedal design is adopted, synchronized with the original equipment layout, and the brake action is seamlessly connected with the software to achieve the most realistic operation effect.

Fuel control lever: used to control the engine speed

And output power. L-idle position, H-high speed position. Use real machine throttle parts for assembly and production, realize throttle linear speed change, to ensure that the trainees feel exactly the same as the real machine, and realize the similarity with the real machine!

Post time: Dec-30-2021